The determination of flames and plasma flow emission spectra and elemental composition using an optical spectrometer.

The formation and study of electrode coatings for energy generation, accumulation and storage facilities.

The melting of ceramic materials and synthesis, application and study of high-temperature ceramic fiber for thermal insulation, fine filter and catalyst production.

The development, research and application of atmospheric, reduced and low-pressure plasma technology.

The employment of water vapor and other gases plasma for biomass and solid fuel conversion, neutralization of hazardous materials and etc.

The catalytic, tribological and protective coatings on various surfaces formed in plasma environment, the study of their properties and applications.

The determination of leaktightness of elastomeric sealing ring type joints of plastics pipes at ambient temperature.

The testing of plastics pipes (PE, PEX, PVC, PP, PB etc.), fittings and hoses of resistance to internal pressure at specified temperature.

Testing of resistance of plastics pipes to external blows at specified temperature.

The system is used for the various composition (metals, semiconductors and oxides) and structure film synthesis using electron beam physical vapour deposition technology.

Physical vapour deposition system is designed for the deposition of metallic, semiconductive and oxide thin films/membranes synthesis using magnetron sputtering technique.

Specialized in characterization of electrical properties of materials at high temperatures and under controlled atmosphere.

The purpose of the four point probe is to measure the resistivity of any semiconductor material.

Effective instrument for performing surface hardness measurements on metals, plastics, rubbers, ceramics, and many other materials.

The equipment provide precision surface topography measurements on a wide variety of substrates and come with the low force frictionless pivot stylus head and a force control feedback system.

Atomic force microscopy is versatile and powerful microscopy technology for studying samples at nanoscale with high resolution.

PCTPro-2000 is a fully automated Sievert instrument for measuring gas sorption properties kinetics and thermodynamics) of materials, especially for hydrogen storage materials.

High temperature electric tube furnace for heating of samples in the air.

A glove box is a sealed container used to manipulate materials where a separate atmosphere is desired.

Ball milling apparatus can realize planetary ball milling process for rapid batch wise ultra fine grinding down to colloidal fineness of hard to soft materials dry or in suspensions.

It is designed to weigh small amounts of material at very high accuracies.

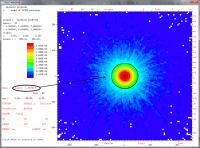

Dynamic registration of Raman scattering spectra in the liquid or gas flow (measurement of material concentration profiles).

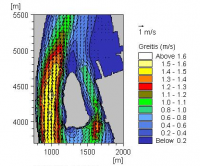

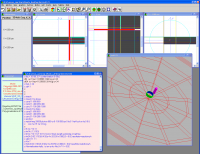

Simultaneous measurement of all three velocity components in liquid or gas flow.

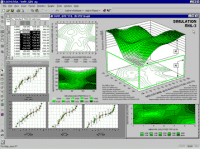

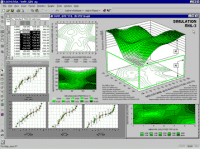

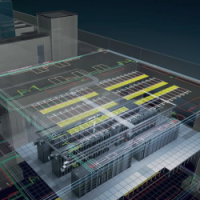

Various HPC-demanding applications (CFD, structural, probabilistic and other analysis).

Infrared camerais a device that forms an image using infrared radiation.

Microscope is designated for the optical investigation of magnified (up to 1000x) objects which are not visible with eye.

Equipment is used for the non-destructive analysis of all types of samples including powders and thin films.

Surface structure and morphology analysis (together wit EDS elemental analysis) of conductive, semi conductive and non conductive samples.

High resolution UV-visible light spectrophotometer suitable for qualitative and quantitative analysis of both liquid and solid state samples.

Equipment is designed for measurement of nitrogen, oxygen, and hydrogen amount in a wide variety of metals and other inorganic materials, employing the inert gas fusion principle. Also equipment has possibility to determine gas release from surface contaminated sample which is achieved by pre-treatment of sample with various gas mixtures prepared by special gas premixer.

Bulk elemental analysis of metals, alloys and other substances and for qualitative and quantitative depth profiling of thin film/layer systems with conductive and non-conductive layers, and for detecting changes in chemical composition of sample surface compared to the subsurface material.

Equipment is designated for the XPS analysis of various samples (including thin films and nanopowders) for the determination of elemental and chemical composition.

Equipment is designated for the Auger electron spectroscopy and Auger electron microscopy analysis of sample surfaces, nanometric particles at the surface and other nanometric features including interface between thin films and their substrate.

Determination of Vicat softening temperature and the temperature of deflection under the load of plastics.

Testing of resistance of plastics pipes and other products of composite materials to solvents impact (methylenchloride, etc.) at specified temperature.

Research on composite and plastic materials (conditioning, aging and corrosion properties) under specified performance parameters and conditioning conditions.

Investigation of polymeric, metallic, composite materials, coatings. EDS spectrometer allows determination of elemental composition.

Determination of specific surface area , porosity and pore distribution of solid state materials.

Qualitative determination of chemical elements.

Universal hardness testing system for micro- and macro- hardness testing.

Multi-purpose instrument for investigation of potenciostatic/galvanostatic, potentiodynamic/ galvanodynamic processes, elektrochemical impedance, corrosion processes, corrosion kinetics, inhibitors and protective coatings, polarisation processes, electrode kinetics, etc.

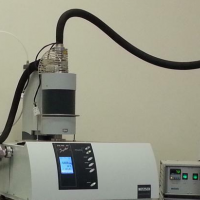

The instrument allows determination of specific heat, phase transition, thermodynamic properties (decomposition behaviour, glass transitions, crystallization and etc.) of metals, polymers, fillers, organic materials, nanocomposites.

Metal analyzer – optical emission spectrometer is aimed at determination of elemental composition of ferrous and non-ferrous metals.

Determination of melt mass-flow rate and melt volume-flow rate of the thermoplastics under specified conditions of temperature and load.

Determination of compressive, bending, stiffness, tensile properties of the materials and similar tests at static and low-cycle operating modes; Investigation of the characteristics of the materials under specified conditions.

For single-phase, two-phase flow processes and high-speed shooting and analysis.

The purpose of the spectrometer is various solid, liquid and gaseous products infrared (IR) analysis, elemental composition of various materials determination.

Fast and accurate exhaust gas and smoke analysis. Measurement of CO, CO2, CxHy, SO2, O2, NO, NO2, H2 concentrations in gas mixtures.

The probe is used for diagnostics of non-equilibruim or equilibrium plasmas, temperature and concentration measurement of electrons, ions and radicals.

The purpose of the device is formation of coatings on various substrates in the ambient of atmospheric pressure plasma.

Ideal for isolation of low frequency vibrations (up to 2 Hz) and are used to isolate vibration from sensitive lab equipment.

A high performance power supply for plasma generators and other devices.

Equipment is designed for measuring concentration of solid particles in air/gas and also for determination of combustion gas composition.

Computer equipment for large-scale computing.

Seminar hall rental.

Screw compressor for compressed air supply.

Processing of signals from thermocouples.

Contactless solid surface temperature analysis (important in the solid surface tension effect analysis; determination of the surface danger of overheating.

Temperature analysis of micro surfaces (such as electronic chips).

Contactless fluid temperature analysis.

Flow (various form of channels, pipes and tanks) visualization and multi-faceted analysis.

Flow (various form of channels, pipes and tanks) visualization and multi-faceted analysis.

Thermal analysis of materials with evolved gas analysis by FTIR and GCMS methods.

Determination of heating value of biofuel, mixtures and calorific waste for determination of suitability of combustion in industrial furnaces.

Applicable for combustion process diagnostics, analysis of other fast processes where optical sensitivity is necessary.

Applicable for the spectral analysis of liquid, solid and gaseous samples of organic or non-organic origin, and dynamic mode of spectral analysis of evolved gases.

Used for the analysis of the products from biofuel thermal destruction (gasification) and combustion.

Solid fuel and high-calorie waste sample preparation for supply them to the analytical instruments and making suitable working conditions for samples mineralization.

The system is intended to use in studies of biofuel combustion efficiency.

Determination Cl, F, Br concentration in the fuel to assess the potential environmental impact of harmful elements and fuel quality indicators.

For various biomass pellets combustion parameters and emissions studies.

Studies of gasification process of solid recovered fuels, i.e., separation of synthesized gas phase in the reactor and subsequent determination of the gas parameters and its application.

To visualize ash melting state and analyze conditions to get information about ash softening, melting processes, depending on the temperature or its gradient values changes.

The influence of the humidity of air supplied for combustion on combustion process efficiency.

Studies on measurement accuracy of air humidity sensors.

Studies on fluid and gas dynamics at low speeds near the surface of the membrane and various trace elements, surface fouling.

The calorific analysis of natural, pyrolysis, liquefied petroleum gas, biogas and gas mixtures.

Heat flow visualization and measurement.

Combustion analysis of heating equipment (boilers, fireplaces, etc.) fired with solid and liquid fuel at operation site.

Determination and analysis of ash content, volatile matter and volatile composition of biofuels and recovered fuels Analysis of materials state transitions.

Major and minor element analysis of liquid and solid organic and mineral compounds of biofuels and recovered fuel.

Measurements of air velocity and air velocity pulsations, performing studies in laboratory as well as field applications.

Solid and liquid fuels, including biofuels and recovered fuel samples weighing in fuel moisture and ash analysis.

Non-invasive liquid (coolant) flow measurements in pipes of experimental and technological equipment and systems.

Performance tests of flow meters installed in large diameter pipes at operating conditions.

Analysis of the main chemical elements C / H / N / S and O in solid and liquid fuels, including biofuels and recovered fuels.

Research and testing of thermal equipment (boilers, fireplaces, etc.) with solid biomass and recovered fuel, and with liquid and gaseous fuels.

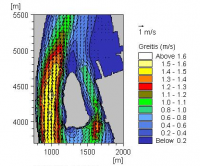

Exploration and development of water and heat transferred with water measurement methods for large diameter pipes DN ≤ 500 and analyze the flow structure in the channels of various forms.

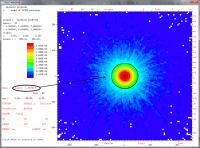

Studies of the particles dynamics in liquid and gas flows and flows interaction with surfaces and flow round bodies in order to increase efficiency of combustion processes and water treatment in plants and as well as to model momentum and heat transfer processes.

Very small air (gas) flow measurement in small-diameter channels or streams flowing through membranes;

Air-gas (sample) volume measurements at various gas formation and quantitative characteristics of analysers.

Evaluation of fuel quality, prices, quantities of heat and, performance parameters of thermal equipment.

Height 50 m, aluminium lattice structure, mounted on steal plate, guyed with wires with attached measurement equipment.

Measurements of wind speed, direction, atmospheric pressure, temperature and humidity.

Bruel&Kjaer high quality noise level analyzer with sound level calibrator.

Particularly precise (6 nm spatial resolution, 2-3 atomic monolayers volume (depth) resolution) identification of surface and volumetric (up to 1-2 μm depth) derivatives, determination of elemental composition, obtainment of chemical (bond) information. Problems and limitations can be found when testing dielectric specimens in particular.

Particularly precise (6 nm spatial resolution, 2-3 atomic monolayers volume (depth) resolution) identification of surface and volumetric (up to 1-2 μm depth) derivatives, determination of elemental composition, obtainment of chemical (bond) information. Problems and limitations can be found when testing dielectric specimens in particular.

Quick, low-precision (spatial accuracy about 2-4 millimeters, profiling depth precision tens-hundreds nanometers) qualitative and quantitative elemental composition analysis. Ability to perform depth profiling, composition control and comparison between surface and deeper layers.

Using inert gas fusion principle we carry out an accurate analysis of even very small amounts of nitrogen, oxygen and hydrogen in various materials. Measurements require up to 1-2g of the test substance that is melted at high temperature during the analysis and the amount of gas released is measured.

Qualitative and quantitative measurements of optical bandwidth in the spectral range of 163-1100 nm.

Variable pressure scanning electron microscope can be used to analyze both conductive and dielectric samples. It is also possible to analyze biological objects with certain limitations. SEM resolution at 30 kV accelerating voltage is 3 nm, while at 3 kV accelerating voltage, 8-10 nm resolution is achieved. We can create images with both secondary and reflective electron detectors, so there is a possibility to separately highlight the unevenness of sample morphology, elemental composition, and extract detailed pseudo 3D images.

Quantitative and qualitative determination of the elemental composition of the sample by detecting chemical elements from Boro5 to Americio95 at the selected point (spatial resolution 1-2 μm, depending on the measurement conditions, information is obtained from 0.5-2 μm depth). It is also possible to map the distribution of individual chemical elements in the sample area.

All crystalline phases in the sample can be determined by one measurement. There are also extended possibilities for diffraction measurements at the same time controlling the ambient temperature (from liquid nitrogen to 1600 oC) and the surrounding environment (high vacuum can be used or the desired amount of gas (suitable for many gases) up to a maximum pressure of 5 bar).

Ability to perform sample analysis using a high-quality optical microscope with the ability to store images in high-resolution photos. Microscope enhancement is selected between 100, 200, 500 and 1000 times. The photos are made with the NIKON DSF-1Fi digital camera specially designed for optical microscopy with a resolution of 2560 x 1920 pixels.

Database Creation and Management.

Using the Primavera software, a professional large-scale, complex, multi-layered, modern project management and planning is performed.

Evaluation of neutron multiplication coefficient of system, modelling of ionizing radiation and radiation shielding parameters.

The software is used for separate neutron, photon, electron or combined neutron, photon and electron transfer simulation and for calculations of critical neutron multiplication coefficient.

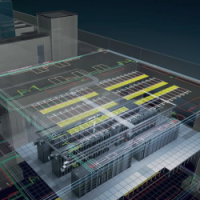

A computer system designed to carry out complex tasks in science and technology requiring a high level of computer resources.

Fire evaluation (simulation) in both nuclear and non-nuclear energy facilities during their operation and during decommissioning.

Determination of the amount and size of particulates emitted with combustion products.

With the assist of geochemical model the models of the course and duration of chemical processes occurring in the water / solid phase systems are created for the simulation of chemical changes, solubility and sorption of pollutants in water / solid phase systems.

The Gardenia model simulates atmospheric rain-water cycles, from their appearance on the ground up to the leakage.

The tasks solvation of various branches of science (technical, engineering, economics, etc.).

Coatings formation on metal, ceramic, etc. substrates, using the materials required by the customer, gas, maintaining the required plasma flow temperature, velocity and other conditions.

Modification, decomposition, melting, fibrillation, gasification of various materials in plasma flow.

Design and manufacture of various gas-plasma generating installations, determination of characteristics of high-temperature gas and plasma flows.

Testing of various materials in the high temperature (air, nitrogen, hydrogen, argon propane, etc.) gas flow.

Filming of various rapid processes using high-speed optical camera, analysis of results.

Determination and analysis of the chemical composition of different materials by infrared spectrometer in wavelength range of 375-7500 cm-1.

Suppress any mechanical vibrations during work.

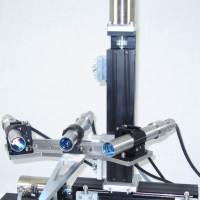

Precise positioning (error up to 0,31 μm) of samples, thermocouples, lasers or other objects weighted up to 3 kg in X, Y, Z axis directions. Maximum travel speed 10 mm/s.

Exhaust gas flow rate 20-100 l/min; temperature up to 1700 oC; possibility to measure gas composition and temperature continuously for up to 8 hours in a day.

NDIR (non-dispersive infrared) technology is used.

Analyzed gas limits: CO – 0-100%, CO2 – 0-50%, CxHy – 0-30,000 ppm, SO2 – 0-5000 ppm, O2 – 0-25%, NO – 0-4000 ppm, NO2 – 0-1000 ppm.

Continuous direct measurement of hydrogen gas concentration and temperature.

Hydrogen concentration limits 0-100% vol.

Determination of tensile, compression, bending, ring stiffness, ring flexibility and other special properties. Determination of the characteristics of small metal samples in static or low-cycle loads conditions.

Determination of mass fluidity and volume fluidity of plastic materials.

Determination of the softening temperature of polymers and composites.

Materials testing in a controlled environment.

Determination of resistance of plastic materials to aggressive environment.

Determination of elemental composition of ferrous and non-ferrous metals.

Quantitative and qualitative determination of chemical elements.

Characterization of thermodynamic characteristics, specific heat, melting, decomposition, crystallization, glass transition temperature, oxidation, reduction, etc. of polymers, metals, fillers, composite materials, organic materials.

Specific surface area determination: BET, Langmiuro, STSA, DFT and BJH methods.

Microporous Surface Analysis: NLDFT, QSDFT, Monte-Carlo, t-plot, alpha, MP, DR and DA methods.

Investigation of corrosion processes of metals, corrosion kinetics, effectiveness evaluation of corrosion inhibitors and protective coatings, evaluation of electrochemical parameters (corrosion current, current density, polarization resistance, kinetics of electrodynamic processes, diffusion, mass transfer, etc.).

Measurement of hardness and microhardness by methods of Vickers, Brinell and Rockwell.

Surface morphology and structure analysis of materials using electronic microscope, determination of surface elemental composition.

Various large-scale benchmark calculations.

Simultaneous measurement of all three speed components.

Raman spectra registration in gases and liquids.

Exercise solution of three-dimensional calculation hydrodynamics (CFD) by finite element and volume methods.

Thermo-hydraulic analysis of design and non-design related accidents of nuclear / thermal power plants and other thermohydraulic equipment and systems.

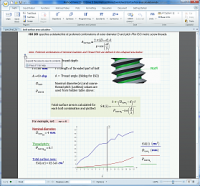

The solution of the dynamic, contact tasks of the degradation mechanics of structures using contact elements and evaluating the nonlinear properties of the material and analysis of the sensitivity of the solutions obtained.

Strength analysis of structures applying static and dynamic loads, using finite element method of movement simulation and validation. Preparation of geometric models for the Abaqus program.

Probabilistic and cyclic fatigue analysis of deterministic finite element models.

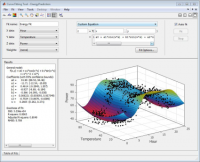

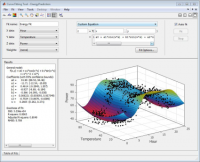

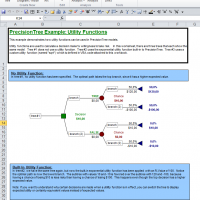

Initial analysis of available statistical data and preparation of visual mathematical model of the object and implementation of various numerical experiments.

Probabilistic risk / safety analysis, assessment of the probability of different events.

3D criticality assessment in complex systems using the Monte Carlo method; Assessment of the criticality of spent nuclear fuel systems combined with fuel combustion and criticality calculation aspects. Analysis of the true values of critical systems for sensitivity of cross sections in 1D / 3D systems. Determination of the maximum true values of the critical system and the minimum critical mass. 2D calculations of flow and combustion. Preparation of cross section libraries according to preselected dependencies. Estimation of neutron and photon flow in geometric regions and at point detectors placed outside the geometry limits.

Comprehensive probabilistic safety analysis and quantitative risk assessment of structural damage and of high and sudden release of harmful substances into the environment.

Development of various mathematical models and their analytical research.

Analysis of static and dynamic processes occurring in trunk pipeline systems (mainly in city centralized heat supply networks, hot or cold water supply, as well as gas and oil pipelines).

Calculations of forces and moments operating in pipeline systems depending on internal pressure, own weight, thermal expansion, thermal displacements of support, wind, external forces and moments, hydro spins, displacement of supports due to seismic and other loads.

The solution of the slow neutron transport equation using the hybrid deterministic / Monte Carlo method. Calculations of reactivity, power profiles, nuclide composition of spent nuclear fuel, calculations of nuclear reaction types, taking into account the characteristics of the cells. Criticality Search. Neutron Spectrum and Flow Analysis.

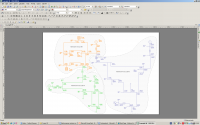

Creating of graphical information in popular DWG file format.

Design of complex 3D mechanisms. Design of molds, cables and belt drives for pipes and piping systems. Motion simulation, dynamic and finite element analysis.

Risk monitoring assessing different operating modes of the (closing and new) nuclear power plants, equipment failure, repairs, periodic testing, different system configurations, environmental factors, etc.

Statistical modeling and probabilistic studies.

Balancing of energy needs, used technologies, energy production and supply sources of the region, while assessing the renewable energy sources, regional macroeconomic indicators.

According to the data provided by the customer about the foreseen technical and economic characteristics of the new technology and the potential deviations of these characteristics, the investment risk is estimated, analysis of the sensitivity of the project results is presented on the basis of various influencing factors, statistical analysis of obtained data and forecasts.

Compilation of mathematical model of Lithuanian power systems and collecting of parameters.

The influence of wind and solar power plants on the Lithuanian PS.

Examination and evaluation of PS parameters, mathematical modelling of networks and control systems, research of system operating modes.

Optimization mathematical models using GAMS, MESSAGE, or other software packages are developed to address this type of tasks. IBM ILOG CPLEX software is used to optimize the solution.

Investigations of the functioning and development of centralised district heating, gas supply systems, product lines and other similar systems.

Macroeconomic studies are conducted covering the interconnections between energy and other sectors of the economy.

Optimization mathematical models using GAMS, MESSAGE, or other software packages are developed to address this type of tasks. IBM ILOG CPLEX software is used to optimize the solution.

The software is used to calculate the dry and wet pollutant sedimentation and to assess the concentrations of pollutants in the air

Using “Microsoft Project” software a large amount of tasks, projects, and resources are organized, filtered and sorted.

The most commonly used fluid flow modeling program in the world

Modelling of the distribution of pollutants (radionuclides) in the environment and engineering systems.

Contactless thermal analysis of solids (important for the analysis of the influence of hard surface tension, for the determination of surface overheating hazards), thermal analysis on micro surfaces (in electronic circuits), contactless analysis of fluid temperature

Laser visualization of the flow (in various shapes channels, pipes, tanks) and a comprehensive analysis

Compressor for compressed air supply.

Additional processing of signals obtained from thermocouples

Laser visualization of the flow (in various shapes channels, pipes, tanks) and a comprehensive analysis

Compressor for compressed air supply.

Additional processing of signals obtained from thermocouples

Modeling of mass motion in engineering and natural environment using numerical methods.

20 seats seminar room with information display device (interactive whiteboard)

The software is aimed for modelling of the radiation doses of ionizing gamma radiation.

Analysis of complex groundwater effects on ground layers using numerical methods.

Simulation of fluid flow and heat transfer through different earth layers.

Using the PROMT NET Professional software the technical text from Russian into English and from English to Russian is translated.

Using Autocad MEP software the design documentation (drawings) are prepared, complex two-dimensional and three-dimensional (spatial) structures are constructed

Determination of thermal value of mass change of the liquid and solid samples.

Determination of the heating value of solid and liquid fuels and organic waste, kJ/kg

Determination of non-flammable fraction in solid and liquid fuels and organic waste, %

Determination of moisture content (%) in solid fuels and organic waste

Evaluation of combustion quality using a high-sensitivity chamber and narrow-band filters

Investigation of biofuel and waste gasification products, solid and liquid organic and inorganic samples using IR beam and analysis with Furje transformation.

Identification of organic compounds (qualitative analysis).

Determination of quantity of inorganic gases and light hydrocarbons in the gaseous phase.

Determination of aromatic hydrocarbons according to EPA610 method.

The preparation of solid and calorific waste and soft, hard, elastic and fibrous materials of 0,25 ÷ 20 mm fractions. Compression of crushed materials into suitable samples for analysis. Ensuring proper working conditions while mineralizing the samples. Preparation of deionised water for mineralization of samples.

Measurements of temperature, pressure, differential pressure and speed, measurement data collection and recording.

The determination of the Cl, F, Br concentration in the fuel in order to assess possible environmental pollution with harmful elements and evaluation of fuel quality indicators.

Research of furnaces up to 25 kW fired with biofuel pellets.

Scientific research on solid fuel gasification in order to find wider applications or to improve quality.

It is intended to analyze the ash melting state and conditions and to visualize how the softening and melting processes of ash take place, depending on the temperature or variation of its gradient value.

Investigations of low velocity liquid and gas dynamics at surfaces, membranes and various microelements, surface contamination, motion and mass transfer processes in capillary systems.

Identification and analysis of upper and lower heating values of gaseous fuels, including biofuels and recovered fuels. Determination and analysis of upper and lower heating values of other calorific materials (eg sewage sludge, waste, etc.).

Measurement and visualization of heat flux from surfaces for determination of heat loss, its location, insulation efficiency.

Measurement of liquid flow and speed in the pipelines through a transparent window in case of scientific research and operating conditions.

Determination of composition of combustion products (CO, CO2, NO, NOx, CiHy, O2, SO2) for the evaluation of the efficiency of thermal equipment, fuel combustion rate, emissions to environment under research and operational conditions; optimization of device operating regimes.

Identification of fuel quality indicators performing research and development.

Determination of fuel elements in order to assess the fuel quality indicators and possible environmental pollution with harmful elements.

Measurement of air flow characteristics in scientific research and practical applications.

Precise measurements of fuel humidity and ash content, assessment of fuel quality indicators and combustion rate.

Non-invasive measurements of flow rates in pipelines (25 … 1500 mm) under laboratory and operational conditions.

The determination of the chemical elements C/H/N/S and O in the fuel, evaluation of its qualitative and quantitative indicators.

The determination of composition (CO, CO2, NO, NOx, CiHy, O2, SO2) of combustion products for the evaluation of the efficiency of thermal equipment, fuel combustion and emissions to the environment.

The scientific research of visualization of the internal flow structures in the channels and flow aroud of various bodies and surfaces.

The measurements of air (gases) volumes transmitted through membranes, filters, dosing devices; volumetric calibration.

The determination of the upper and lower calorific values and analysis of solid and liquid fuels, including biofuels and recovered fuels.

The measurement of wind speed and direction, maintenance of equipment, data analysis.

The calculation of wind energy resources, the planning of wind power park layout, the economic calculations.

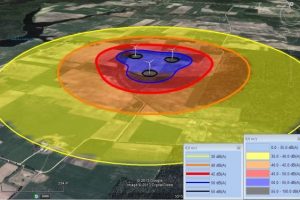

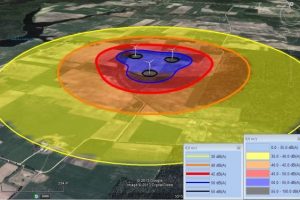

Simulation and visualization of blades shadow zones around wind power plant.

Modeling and visualization of noise dispersion zones around noise sources.

Measurement of noise level in industrial and residential environments.

Comprehensive software, maintaining the integrated data analysis, graphics, database management, and custom application development system featuring a wide selection of basic and advanced analytic procedures.

Software for analysis for different power plants (to be closed and new) risk monitoring with taking into account of the operational modes, failures of equipment, repairs, periodic stress tests, different system configurations, environmental factors, and other.

Digital modeling of waves, hydrodynamic processes and sediment transport in water bodies(two-dimensional models).

Software package for construction and design to work drawings of multi-purpose equipment and vehicles. Strength verification with engineering-level calculus.

Drawing software for systematization and automatization of the design documentation (drawings) preparation.

Universal software for solving of neutron transport equation by applying hybrid deterministic and Monte Carlo method.

Software for calculation of forces and moments acting on piping systems, depending on the internal pressure, own weight, thermal expansion, thermal displacement of supports, wind, external forces and moments waterhammer, seismic, displacements of supports due to seismic and other loads.

Software for modeling of complex networks of district heating systems, and calculation of static hydraulic pressure and thermodynamic parameters (heat transfer, coolant temperature by assessing system inertia as well) at any section of the heating network.

Mathematical software package, with large library of specialized tools for different types of modeling.

Software for risk monitoring by considering different operational modes of nuclear power plants, equipment failures, repairs, periodic stress tests, different system configurations, environmental factors, and so on.

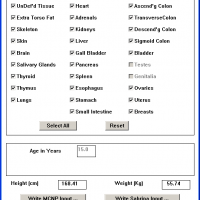

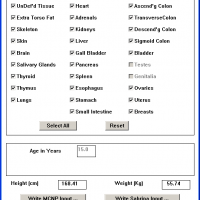

Software for generation of human anthropomorphic phantoms of arbitrary age (from infant through adult).

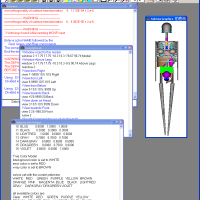

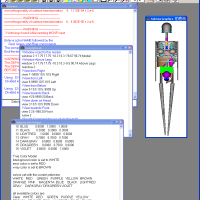

Graphical tool software for geometry error checking in MCNP (X) as well as Monte Carlo simulated particle trajectory visualization and conversion of solid body geometry descriptions to the MCNP surface geometry.

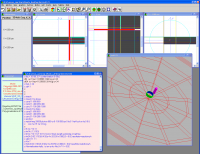

Geometry editor software designed to accelerate construction of MCNP (X) and other geometric models from architectural and other layouts.

Monte Carlo code that can be used for neutron, photon, electron, or coupled neutron/photon/electron transport, including the capability to calculate eigenvalues for critical systems.

Software for:

Software for risk analysis using Monte Carlo simulation to show many possible outcomes and how likely they are to occur.

Versatile mathematical programming package allows to perform an analysis of the available data and select the best model of the object. Moreover, it is a computer math system, which is used as a statistical data analysis tool also.

3D parametric modeling system software for:

Software for simulation of the reactor core melt down, debris formation and accumulation on the bottom plate, plate disintegration, overheating and damage progression in the core and surrounding structures.

Analysis of processes in reactors / power plants at design basis and beyond basis design accident conditions, including severe accidents.

Simulation of multi-phase flows.

The modelling and solutions optimization of pipeline systems (gas, heat supply systems).

The optimization software IBM ILOG CPLEX for solving linear and mixed integer programming problems.

@RISK employs Monte Carlo method to extend the space of solutions yielded by programme in Microsoft Excel, with respect to the expected violations of parameter values.

Sustainable harmonization of energy demand with energy use technologies and energy efficiency promotion measures.

Mathematical modeling and analysis of modeling results.

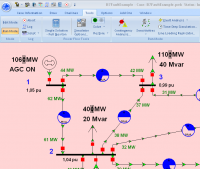

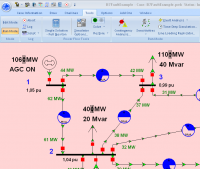

Power flow solution.

Analysis of electrical, pipe networks with topological characteristics and reliability evaluation.

Detailed research of electrical power system.

NRG-sert 2 is used for building energy efficiency certification.

Fire simulation in various rooms.

This geochemical simulation program aloud us creating various models of chemical processes that take part in the analyzed water/solid phase systems; these models are used for simulation of pollutants’ chemical changes, solubility and sorption in water/solid phase systems.

Environment impact assessment.

Program is designed for simulation of the rainfall-water cycle from the moment the water reaches the ground till its final locations.

System for database management.

This computer program because of its environment of specialized toolboxes are widely used in various branches of science (technical, engineering, economic, etc.).

Nuclear facility design and safety analysis.

Creating graphs and graphical data processing.

Program is designed especially for mechanical, electrical, plumbing and heat network designers and drafters.

Translation program.

Simulation of pollutants distribution in nature and engineered systems.

The most popular simulation program of fluid flow worldwide.

It is used to provide a multitude of ways to organize, filter and sort activities, projects, and resources.

Program for professional project management designed to handle large-scale, highly sophisticated and multifaceted projects.

Complex groundwater influence to ground layers analysis.

Simulation of the transport of mass within engineered and natural environment.

Software is designed for evaluation of dose from sky scattered (skyshine) gamma ray radiation.

Program is designed to model multiphase multicomponent fluid and heat flow analysis in porous and fractured environment.

Software for calculation and visualisation of wind power resources.

Modeling of wind power resources, wind farm planning, modeling of wind turbine noise and flicker.

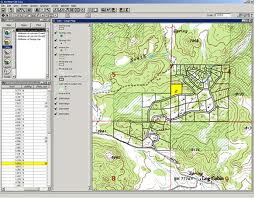

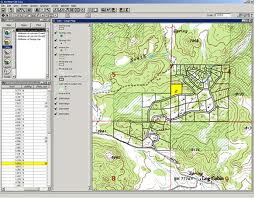

Management and analysis of digital maps and other visual data. Creation, management and analysis of visual data, illustration of reports.

Particularly precise (6 nm spatial resolution, 2-3 atomic monolayers volume (depth) resolution) identification of surface and volumetric (up to 1-2 μm depth) derivatives, determination of elemental composition, obtainment of chemical (bond) information. Problems and limitations can be found when testing dielectric specimens in particular.

Particularly precise (6 nm spatial resolution, 2-3 atomic monolayers volume (depth) resolution) identification of surface and volumetric (up to 1-2 μm depth) derivatives, determination of elemental composition, obtainment of chemical (bond) information. Problems and limitations can be found when testing dielectric specimens in particular.

Quick, low-precision (spatial accuracy about 2-4 millimeters, profiling depth precision tens-hundreds nanometers) qualitative and quantitative elemental composition analysis. Ability to perform depth profiling, composition control and comparison between surface and deeper layers.

Using inert gas fusion principle we carry out an accurate analysis of even very small amounts of nitrogen, oxygen and hydrogen in various materials. Measurements require up to 1-2g of the test substance that is melted at high temperature during the analysis and the amount of gas released is measured.

Qualitative and quantitative measurements of optical bandwidth in the spectral range of 163-1100 nm.

Variable pressure scanning electron microscope can be used to analyze both conductive and dielectric samples. It is also possible to analyze biological objects with certain limitations. SEM resolution at 30 kV accelerating voltage is 3 nm, while at 3 kV accelerating voltage, 8-10 nm resolution is achieved. We can create images with both secondary and reflective electron detectors, so there is a possibility to separately highlight the unevenness of sample morphology, elemental composition, and extract detailed pseudo 3D images.

Quantitative and qualitative determination of the elemental composition of the sample by detecting chemical elements from Boro5 to Americio95 at the selected point (spatial resolution 1-2 μm, depending on the measurement conditions, information is obtained from 0.5-2 μm depth). It is also possible to map the distribution of individual chemical elements in the sample area.

All crystalline phases in the sample can be determined by one measurement. There are also extended possibilities for diffraction measurements at the same time controlling the ambient temperature (from liquid nitrogen to 1600 oC) and the surrounding environment (high vacuum can be used or the desired amount of gas (suitable for many gases) up to a maximum pressure of 5 bar).

Ability to perform sample analysis using a high-quality optical microscope with the ability to store images in high-resolution photos. Microscope enhancement is selected between 100, 200, 500 and 1000 times. The photos are made with the NIKON DSF-1Fi digital camera specially designed for optical microscopy with a resolution of 2560 x 1920 pixels.

Using the Primavera software, a professional large-scale, complex, multi-layered, modern project management and planning is performed.

Evaluation of neutron multiplication coefficient of system, modelling of ionizing radiation and radiation shielding parameters.

The software is used for separate neutron, photon, electron or combined neutron, photon and electron transfer simulation and for calculations of critical neutron multiplication coefficient.

A computer system designed to carry out complex tasks in science and technology requiring a high level of computer resources.

Fire evaluation (simulation) in both nuclear and non-nuclear energy facilities during their operation and during decommissioning.

Determination of the amount and size of particulates emitted with combustion products.

With the assist of geochemical model the models of the course and duration of chemical processes occurring in the water / solid phase systems are created for the simulation of chemical changes, solubility and sorption of pollutants in water / solid phase systems.

The Gardenia model simulates atmospheric rain-water cycles, from their appearance on the ground up to the leakage.

The tasks solvation of various branches of science (technical, engineering, economics, etc.).

Coatings formation on metal, ceramic, etc. substrates, using the materials required by the customer, gas, maintaining the required plasma flow temperature, velocity and other conditions.

Modification, decomposition, melting, fibrillation, gasification of various materials in plasma flow.

Design and manufacture of various gas-plasma generating installations, determination of characteristics of high-temperature gas and plasma flows.

Testing of various materials in the high temperature (air, nitrogen, hydrogen, argon propane, etc.) gas flow.

Filming of various rapid processes using high-speed optical camera, analysis of results.

Determination and analysis of the chemical composition of different materials by infrared spectrometer in wavelength range of 375-7500 cm-1.

Suppress any mechanical vibrations during work.

Precise positioning (error up to 0,31 μm) of samples, thermocouples, lasers or other objects weighted up to 3 kg in X, Y, Z axis directions. Maximum travel speed 10 mm/s.

Exhaust gas flow rate 20-100 l/min; temperature up to 1700 oC; possibility to measure gas composition and temperature continuously for up to 8 hours in a day.

NDIR (non-dispersive infrared) technology is used.

Analyzed gas limits: CO – 0-100%, CO2 – 0-50%, CxHy – 0-30,000 ppm, SO2 – 0-5000 ppm, O2 – 0-25%, NO – 0-4000 ppm, NO2 – 0-1000 ppm.

Continuous direct measurement of hydrogen gas concentration and temperature.

Hydrogen concentration limits 0-100% vol.

Determination of tensile, compression, bending, ring stiffness, ring flexibility and other special properties. Determination of the characteristics of small metal samples in static or low-cycle loads conditions.

Determination of mass fluidity and volume fluidity of plastic materials.

Determination of the softening temperature of polymers and composites.

Determination of resistance of plastic materials to aggressive environment.

Determination of elemental composition of ferrous and non-ferrous metals.

Characterization of thermodynamic characteristics, specific heat, melting, decomposition, crystallization, glass transition temperature, oxidation, reduction, etc. of polymers, metals, fillers, composite materials, organic materials.

Specific surface area determination: BET, Langmiuro, STSA, DFT and BJH methods.

Microporous Surface Analysis: NLDFT, QSDFT, Monte-Carlo, t-plot, alpha, MP, DR and DA methods.

Investigation of corrosion processes of metals, corrosion kinetics, effectiveness evaluation of corrosion inhibitors and protective coatings, evaluation of electrochemical parameters (corrosion current, current density, polarization resistance, kinetics of electrodynamic processes, diffusion, mass transfer, etc.).

Measurement of hardness and microhardness by methods of Vickers, Brinell and Rockwell.

Surface morphology and structure analysis of materials using electronic microscope, determination of surface elemental composition.

Exercise solution of three-dimensional calculation hydrodynamics (CFD) by finite element and volume methods.

Thermo-hydraulic analysis of design and non-design related accidents of nuclear / thermal power plants and other thermohydraulic equipment and systems.

The solution of the dynamic, contact tasks of the degradation mechanics of structures using contact elements and evaluating the nonlinear properties of the material and analysis of the sensitivity of the solutions obtained.

Strength analysis of structures applying static and dynamic loads, using finite element method of movement simulation and validation. Preparation of geometric models for the Abaqus program.

Probabilistic and cyclic fatigue analysis of deterministic finite element models.

Initial analysis of available statistical data and preparation of visual mathematical model of the object and implementation of various numerical experiments.

Probabilistic risk / safety analysis, assessment of the probability of different events.

3D criticality assessment in complex systems using the Monte Carlo method; Assessment of the criticality of spent nuclear fuel systems combined with fuel combustion and criticality calculation aspects. Analysis of the true values of critical systems for sensitivity of cross sections in 1D / 3D systems. Determination of the maximum true values of the critical system and the minimum critical mass. 2D calculations of flow and combustion. Preparation of cross section libraries according to preselected dependencies. Estimation of neutron and photon flow in geometric regions and at point detectors placed outside the geometry limits.

Comprehensive probabilistic safety analysis and quantitative risk assessment of structural damage and of high and sudden release of harmful substances into the environment.

Analysis of static and dynamic processes occurring in trunk pipeline systems (mainly in city centralized heat supply networks, hot or cold water supply, as well as gas and oil pipelines).

Calculations of forces and moments operating in pipeline systems depending on internal pressure, own weight, thermal expansion, thermal displacements of support, wind, external forces and moments, hydro spins, displacement of supports due to seismic and other loads.

The solution of the slow neutron transport equation using the hybrid deterministic / Monte Carlo method. Calculations of reactivity, power profiles, nuclide composition of spent nuclear fuel, calculations of nuclear reaction types, taking into account the characteristics of the cells. Criticality Search. Neutron Spectrum and Flow Analysis.

Design of complex 3D mechanisms. Design of molds, cables and belt drives for pipes and piping systems. Motion simulation, dynamic and finite element analysis.

Risk monitoring assessing different operating modes of the (closing and new) nuclear power plants, equipment failure, repairs, periodic testing, different system configurations, environmental factors, etc.

Balancing of energy needs, used technologies, energy production and supply sources of the region, while assessing the renewable energy sources, regional macroeconomic indicators.

According to the data provided by the customer about the foreseen technical and economic characteristics of the new technology and the potential deviations of these characteristics, the investment risk is estimated, analysis of the sensitivity of the project results is presented on the basis of various influencing factors, statistical analysis of obtained data and forecasts.

Compilation of mathematical model of Lithuanian power systems and collecting of parameters.

The influence of wind and solar power plants on the Lithuanian PS.

Examination and evaluation of PS parameters, mathematical modelling of networks and control systems, research of system operating modes.

Optimization mathematical models using GAMS, MESSAGE, or other software packages are developed to address this type of tasks. IBM ILOG CPLEX software is used to optimize the solution.

Investigations of the functioning and development of centralised district heating, gas supply systems, product lines and other similar systems.

Macroeconomic studies are conducted covering the interconnections between energy and other sectors of the economy.

Optimization mathematical models using GAMS, MESSAGE, or other software packages are developed to address this type of tasks. IBM ILOG CPLEX software is used to optimize the solution.

The software is used to calculate the dry and wet pollutant sedimentation and to assess the concentrations of pollutants in the air

Using “Microsoft Project” software a large amount of tasks, projects, and resources are organized, filtered and sorted.

The most commonly used fluid flow modeling program in the world

Modelling of the distribution of pollutants (radionuclides) in the environment and engineering systems.

Contactless thermal analysis of solids (important for the analysis of the influence of hard surface tension, for the determination of surface overheating hazards), thermal analysis on micro surfaces (in electronic circuits), contactless analysis of fluid temperature

Laser visualization of the flow (in various shapes channels, pipes, tanks) and a comprehensive analysis

Compressor for compressed air supply.

Additional processing of signals obtained from thermocouples

Laser visualization of the flow (in various shapes channels, pipes, tanks) and a comprehensive analysis

Compressor for compressed air supply.

Additional processing of signals obtained from thermocouples

Modeling of mass motion in engineering and natural environment using numerical methods.

20 seats seminar room with information display device (interactive whiteboard)

The software is aimed for modelling of the radiation doses of ionizing gamma radiation.

Analysis of complex groundwater effects on ground layers using numerical methods.

Simulation of fluid flow and heat transfer through different earth layers.

Using the PROMT NET Professional software the technical text from Russian into English and from English to Russian is translated.

Using Autocad MEP software the design documentation (drawings) are prepared, complex two-dimensional and three-dimensional (spatial) structures are constructed

Determination of the heating value of solid and liquid fuels and organic waste, kJ/kg

Determination of non-flammable fraction in solid and liquid fuels and organic waste, %

Evaluation of combustion quality using a high-sensitivity chamber and narrow-band filters

Investigation of biofuel and waste gasification products, solid and liquid organic and inorganic samples using IR beam and analysis with Furje transformation.

Determination of quantity of inorganic gases and light hydrocarbons in the gaseous phase.

The preparation of solid and calorific waste and soft, hard, elastic and fibrous materials of 0,25 ÷ 20 mm fractions. Compression of crushed materials into suitable samples for analysis. Ensuring proper working conditions while mineralizing the samples. Preparation of deionised water for mineralization of samples.

Measurements of temperature, pressure, differential pressure and speed, measurement data collection and recording.

The determination of the Cl, F, Br concentration in the fuel in order to assess possible environmental pollution with harmful elements and evaluation of fuel quality indicators.

Research of furnaces up to 25 kW fired with biofuel pellets.

Scientific research on solid fuel gasification in order to find wider applications or to improve quality.

It is intended to analyze the ash melting state and conditions and to visualize how the softening and melting processes of ash take place, depending on the temperature or variation of its gradient value.

Investigations of low velocity liquid and gas dynamics at surfaces, membranes and various microelements, surface contamination, motion and mass transfer processes in capillary systems.

Identification and analysis of upper and lower heating values of gaseous fuels, including biofuels and recovered fuels. Determination and analysis of upper and lower heating values of other calorific materials (eg sewage sludge, waste, etc.).

Measurement and visualization of heat flux from surfaces for determination of heat loss, its location, insulation efficiency.

Measurement of liquid flow and speed in the pipelines through a transparent window in case of scientific research and operating conditions.

Determination of composition of combustion products (CO, CO2, NO, NOx, CiHy, O2, SO2) for the evaluation of the efficiency of thermal equipment, fuel combustion rate, emissions to environment under research and operational conditions; optimization of device operating regimes.

Identification of fuel quality indicators performing research and development.

Determination of fuel elements in order to assess the fuel quality indicators and possible environmental pollution with harmful elements.

Measurement of air flow characteristics in scientific research and practical applications.

Precise measurements of fuel humidity and ash content, assessment of fuel quality indicators and combustion rate.

Non-invasive measurements of flow rates in pipelines (25 … 1500 mm) under laboratory and operational conditions.

The determination of the chemical elements C/H/N/S and O in the fuel, evaluation of its qualitative and quantitative indicators.

The determination of composition (CO, CO2, NO, NOx, CiHy, O2, SO2) of combustion products for the evaluation of the efficiency of thermal equipment, fuel combustion and emissions to the environment.

The scientific research of visualization of the internal flow structures in the channels and flow aroud of various bodies and surfaces.

The measurements of air (gases) volumes transmitted through membranes, filters, dosing devices; volumetric calibration.

The determination of the upper and lower calorific values and analysis of solid and liquid fuels, including biofuels and recovered fuels.

The measurement of wind speed and direction, maintenance of equipment, data analysis.

The calculation of wind energy resources, the planning of wind power park layout, the economic calculations.

Simulation and visualization of blades shadow zones around wind power plant.

Modeling and visualization of noise dispersion zones around noise sources.

The determination of flames and plasma flow emission spectra and elemental composition using an optical spectrometer.

The formation and study of electrode coatings for energy generation, accumulation and storage facilities.

The melting of ceramic materials and synthesis, application and study of high-temperature ceramic fiber for thermal insulation, fine filter and catalyst production.

The development, research and application of atmospheric, reduced and low-pressure plasma technology.

The employment of water vapor and other gases plasma for biomass and solid fuel conversion, neutralization of hazardous materials and etc.

The catalytic, tribological and protective coatings on various surfaces formed in plasma environment, the study of their properties and applications.

The determination of leaktightness of elastomeric sealing ring type joints of plastics pipes at ambient temperature.

The testing of plastics pipes (PE, PEX, PVC, PP, PB etc.), fittings and hoses of resistance to internal pressure at specified temperature.

Testing of resistance of plastics pipes to external blows at specified temperature.

The system is used for the various composition (metals, semiconductors and oxides) and structure film synthesis using electron beam physical vapour deposition technology.

Physical vapour deposition system is designed for the deposition of metallic, semiconductive and oxide thin films/membranes synthesis using magnetron sputtering technique.

Specialized in characterization of electrical properties of materials at high temperatures and under controlled atmosphere.

The purpose of the four point probe is to measure the resistivity of any semiconductor material.

Effective instrument for performing surface hardness measurements on metals, plastics, rubbers, ceramics, and many other materials.

The equipment provide precision surface topography measurements on a wide variety of substrates and come with the low force frictionless pivot stylus head and a force control feedback system.

Atomic force microscopy is versatile and powerful microscopy technology for studying samples at nanoscale with high resolution.

PCTPro-2000 is a fully automated Sievert instrument for measuring gas sorption properties kinetics and thermodynamics) of materials, especially for hydrogen storage materials.

High temperature electric tube furnace for heating of samples in the air.

A glove box is a sealed container used to manipulate materials where a separate atmosphere is desired.

Ball milling apparatus can realize planetary ball milling process for rapid batch wise ultra fine grinding down to colloidal fineness of hard to soft materials dry or in suspensions.

Comprehensive software, maintaining the integrated data analysis, graphics, database management, and custom application development system featuring a wide selection of basic and advanced analytic procedures.

Software for analysis for different power plants (to be closed and new) risk monitoring with taking into account of the operational modes, failures of equipment, repairs, periodic stress tests, different system configurations, environmental factors, and other.

Digital modeling of waves, hydrodynamic processes and sediment transport in water bodies(two-dimensional models).

Manufacturer: Danijos hidraulikos institutas

Software package for construction and design to work drawings of multi-purpose equipment and vehicles. Strength verification with engineering-level calculus.

Drawing software for systematization and automatization of the design documentation (drawings) preparation.

Universal software for solving of neutron transport equation by applying hybrid deterministic and Monte Carlo method.

Software for calculation of forces and moments acting on piping systems, depending on the internal pressure, own weight, thermal expansion, thermal displacement of supports, wind, external forces and moments waterhammer, seismic, displacements of supports due to seismic and other loads.

Software for modeling of complex networks of district heating systems, and calculation of static hydraulic pressure and thermodynamic parameters (heat transfer, coolant temperature by assessing system inertia as well) at any section of the heating network.

Mathematical software package, with large library of specialized tools for different types of modeling.

Software for risk monitoring by considering different operational modes of nuclear power plants, equipment failures, repairs, periodic stress tests, different system configurations, environmental factors, and so on.

Software for generation of human anthropomorphic phantoms of arbitrary age (from infant through adult).

Graphical tool software for geometry error checking in MCNP (X) as well as Monte Carlo simulated particle trajectory visualization and conversion of solid body geometry descriptions to the MCNP surface geometry.

Geometry editor software designed to accelerate construction of MCNP (X) and other geometric models from architectural and other layouts.

Monte Carlo code that can be used for neutron, photon, electron, or coupled neutron/photon/electron transport, including the capability to calculate eigenvalues for critical systems.

Software for:

Software for risk analysis using Monte Carlo simulation to show many possible outcomes and how likely they are to occur.

Versatile mathematical programming package allows to perform an analysis of the available data and select the best model of the object. Moreover, it is a computer math system, which is used as a statistical data analysis tool also.

3D parametric modeling system software for:

Software for simulation of the reactor core melt down, debris formation and accumulation on the bottom plate, plate disintegration, overheating and damage progression in the core and surrounding structures.

Analysis of processes in reactors / power plants at design basis and beyond basis design accident conditions, including severe accidents.

Dynamic registration of Raman scattering spectra in the liquid or gas flow (measurement of material concentration profiles).

Various HPC-demanding applications (CFD, structural, probabilistic and other analysis).

The modelling and solutions optimization of pipeline systems (gas, heat supply systems).

The optimization software IBM ILOG CPLEX for solving linear and mixed integer programming problems.

@RISK employs Monte Carlo method to extend the space of solutions yielded by programme in Microsoft Excel, with respect to the expected violations of parameter values.

Sustainable harmonization of energy demand with energy use technologies and energy efficiency promotion measures.

Manufacturer: International Energy Agency (IEA)

Mathematical modeling and analysis of modeling results.

Manufacturer: The MathWorks, Inc.

Analysis of electrical, pipe networks with topological characteristics and reliability evaluation.

Manufacturer: Siemens AG

Detailed research of electrical power system.

Manufacturer: Siemens Energy, Inc., Power Technologies International

NRG-sert 2 is used for building energy efficiency certification.

Microscope is designated for the optical investigation of magnified (up to 1000x) objects which are not visible with eye.

Equipment is used for the non-destructive analysis of all types of samples including powders and thin films.

Surface structure and morphology analysis (together wit EDS elemental analysis) of conductive, semi conductive and non conductive samples.

High resolution UV-visible light spectrophotometer suitable for qualitative and quantitative analysis of both liquid and solid state samples.

Equipment is designed for measurement of nitrogen, oxygen, and hydrogen amount in a wide variety of metals and other inorganic materials, employing the inert gas fusion principle. Also equipment has possibility to determine gas release from surface contaminated sample which is achieved by pre-treatment of sample with various gas mixtures prepared by special gas premixer.

Bulk elemental analysis of metals, alloys and other substances and for qualitative and quantitative depth profiling of thin film/layer systems with conductive and non-conductive layers, and for detecting changes in chemical composition of sample surface compared to the subsurface material.

Equipment is designated for the XPS analysis of various samples (including thin films and nanopowders) for the determination of elemental and chemical composition.

Equipment is designated for the Auger electron spectroscopy and Auger electron microscopy analysis of sample surfaces, nanometric particles at the surface and other nanometric features including interface between thin films and their substrate.

Determination of Vicat softening temperature and the temperature of deflection under the load of plastics.

Testing of resistance of plastics pipes and other products of composite materials to solvents impact (methylenchloride, etc.) at specified temperature.

Research on composite and plastic materials (conditioning, aging and corrosion properties) under specified performance parameters and conditioning conditions.

Investigation of polymeric, metallic, composite materials, coatings. EDS spectrometer allows determination of elemental composition.

Determination of specific surface area , porosity and pore distribution of solid state materials.

Universal hardness testing system for micro- and macro- hardness testing.

Multi-purpose instrument for investigation of potenciostatic/galvanostatic, potentiodynamic/ galvanodynamic processes, elektrochemical impedance, corrosion processes, corrosion kinetics, inhibitors and protective coatings, polarisation processes, electrode kinetics, etc.

The instrument allows determination of specific heat, phase transition, thermodynamic properties (decomposition behaviour, glass transitions, crystallization and etc.) of metals, polymers, fillers, organic materials, nanocomposites.

Metal analyzer – optical emission spectrometer is aimed at determination of elemental composition of ferrous and non-ferrous metals.

Determination of melt mass-flow rate and melt volume-flow rate of the thermoplastics under specified conditions of temperature and load.

Determination of compressive, bending, stiffness, tensile properties of the materials and similar tests at static and low-cycle operating modes; Investigation of the characteristics of the materials under specified conditions.

For single-phase, two-phase flow processes and high-speed shooting and analysis.

The purpose of the spectrometer is various solid, liquid and gaseous products infrared (IR) analysis, elemental composition of various materials determination.

Fast and accurate exhaust gas and smoke analysis. Measurement of CO, CO2, CxHy, SO2, O2, NO, NO2, H2 concentrations in gas mixtures.

The probe is used for diagnostics of non-equilibruim or equilibrium plasmas, temperature and concentration measurement of electrons, ions and radicals.

The purpose of the device is formation of coatings on various substrates in the ambient of atmospheric pressure plasma.

Ideal for isolation of low frequency vibrations (up to 2 Hz) and are used to isolate vibration from sensitive lab equipment.

A high performance power supply for plasma generators and other devices.

Equipment is designed for measuring concentration of solid particles in air/gas and also for determination of combustion gas composition.

This geochemical simulation program aloud us creating various models of chemical processes that take part in the analyzed water/solid phase systems; these models are used for simulation of pollutants’ chemical changes, solubility and sorption in water/solid phase systems.

Program is designed for simulation of the rainfall-water cycle from the moment the water reaches the ground till its final locations.

This computer program because of its environment of specialized toolboxes are widely used in various branches of science (technical, engineering, economic, etc.).

Screw compressor for compressed air supply.

Program is designed especially for mechanical, electrical, plumbing and heat network designers and drafters.

It is used to provide a multitude of ways to organize, filter and sort activities, projects, and resources.

Program for professional project management designed to handle large-scale, highly sophisticated and multifaceted projects.

Software is designed for evaluation of dose from sky scattered (skyshine) gamma ray radiation.

Program is designed to model multiphase multicomponent fluid and heat flow analysis in porous and fractured environment.

Contactless solid surface temperature analysis (important in the solid surface tension effect analysis; determination of the surface danger of overheating.

Temperature analysis of micro surfaces (such as electronic chips).

Contactless fluid temperature analysis.

Flow (various form of channels, pipes and tanks) visualization and multi-faceted analysis.

Flow (various form of channels, pipes and tanks) visualization and multi-faceted analysis.

Thermal analysis of materials with evolved gas analysis by FTIR and GCMS methods.

Determination of heating value of biofuel, mixtures and calorific waste for determination of suitability of combustion in industrial furnaces.

Applicable for combustion process diagnostics, analysis of other fast processes where optical sensitivity is necessary.

Applicable for the spectral analysis of liquid, solid and gaseous samples of organic or non-organic origin, and dynamic mode of spectral analysis of evolved gases.

Used for the analysis of the products from biofuel thermal destruction (gasification) and combustion.

Solid fuel and high-calorie waste sample preparation for supply them to the analytical instruments and making suitable working conditions for samples mineralization.

The system is intended to use in studies of biofuel combustion efficiency.

Determination Cl, F, Br concentration in the fuel to assess the potential environmental impact of harmful elements and fuel quality indicators.

For various biomass pellets combustion parameters and emissions studies.

Studies of gasification process of solid recovered fuels, i.e., separation of synthesized gas phase in the reactor and subsequent determination of the gas parameters and its application.

To visualize ash melting state and analyze conditions to get information about ash softening, melting processes, depending on the temperature or its gradient values changes.

The influence of the humidity of air supplied for combustion on combustion process efficiency.

Studies on measurement accuracy of air humidity sensors.

Studies on fluid and gas dynamics at low speeds near the surface of the membrane and various trace elements, surface fouling.

Manufacturer: Dantec Dynamics

The calorific analysis of natural, pyrolysis, liquefied petroleum gas, biogas and gas mixtures.

Combustion analysis of heating equipment (boilers, fireplaces, etc.) fired with solid and liquid fuel at operation site.

Determination and analysis of ash content, volatile matter and volatile composition of biofuels and recovered fuels Analysis of materials state transitions.

Major and minor element analysis of liquid and solid organic and mineral compounds of biofuels and recovered fuel.

Measurements of air velocity and air velocity pulsations, performing studies in laboratory as well as field applications.

Manufacturer: Dantec Dynamics

Solid and liquid fuels, including biofuels and recovered fuel samples weighing in fuel moisture and ash analysis.

Non-invasive liquid (coolant) flow measurements in pipes of experimental and technological equipment and systems.

Performance tests of flow meters installed in large diameter pipes at operating conditions.

Analysis of the main chemical elements C / H / N / S and O in solid and liquid fuels, including biofuels and recovered fuels.

Research and testing of thermal equipment (boilers, fireplaces, etc.) with solid biomass and recovered fuel, and with liquid and gaseous fuels.

Exploration and development of water and heat transferred with water measurement methods for large diameter pipes DN ≤ 500 and analyze the flow structure in the channels of various forms.

Studies of the particles dynamics in liquid and gas flows and flows interaction with surfaces and flow round bodies in order to increase efficiency of combustion processes and water treatment in plants and as well as to model momentum and heat transfer processes.

Manufacturer: Dantec Dynamics

Very small air (gas) flow measurement in small-diameter channels or streams flowing through membranes;

Air-gas (sample) volume measurements at various gas formation and quantitative characteristics of analysers.

Manufacturer: Sierra Instruments

Evaluation of fuel quality, prices, quantities of heat and, performance parameters of thermal equipment.

Software for calculation and visualisation of wind power resources.

Modeling of wind power resources, wind farm planning, modeling of wind turbine noise and flicker.

Management and analysis of digital maps and other visual data. Creation, management and analysis of visual data, illustration of reports.

Height 50 m, aluminium lattice structure, mounted on steal plate, guyed with wires with attached measurement equipment.

Measurements of wind speed, direction, atmospheric pressure, temperature and humidity.

Manufacturer: LSI Lastem

Bruel&Kjaer high quality noise level analyzer with sound level calibrator.